Skip to content

- Material Compounding

- Production

- Inspection

- R&D & Testing

- In-House Compounded Materials

- Certification & Compliances

- A climate controlled room with a completely access controlled automated chemical weighing system to ensure accuracy with weights and measures.

- 75 ltr & 35 ltr kneader for preparing master batches.

- Multiple two roll mixing mills with stock blenders.

- Calendars to ensure precise thickness and dispersion.

- Climate controlled rooms for pre and post compounding.

- Rubber pre-formers with cooling facility.

- Automated strip cutting machine.

- Isolated room for color compounded material.

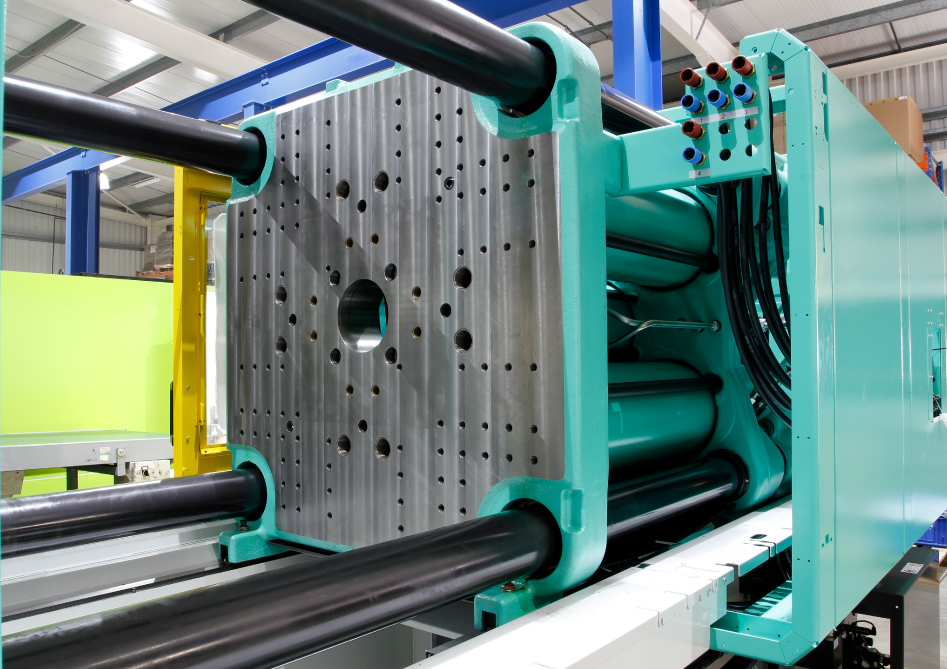

- MultipleTransfer, Compression & Vacuum compression molding presses (250, 350, 400 & 650 Tonnage).

- Metal surface treatment facility for preparing parts for molding and bonding operation.

- Multiple gasket cutting and punching presses.

- Multiple laser cuttingbeds (6×8 ft.)

- Multiple Fecken Kirfel slicing and splitting machines.

- Sanding machineto achieve accurate thicknesses.

- Nitrogen cryogenic de-flashing machine

- Clean room for contamination control.

- Automated ultrasonic washing machine for contamination removal.

- sCuring Ovens for enhancing the physical properties of rubber molded parts.

- Charging Ovens for heating cork rubber blocks.

- Robotic arm lip trimming machines to achieve de-flashing in critical areas of seals.

- Automated de-flashing special purpose machines for flash removal.

- Band saw cutting machine.

- Laser engraving & inkjet printing machines for engraving and marking on parts.

- AI Based visual inspection machine for finished parts.

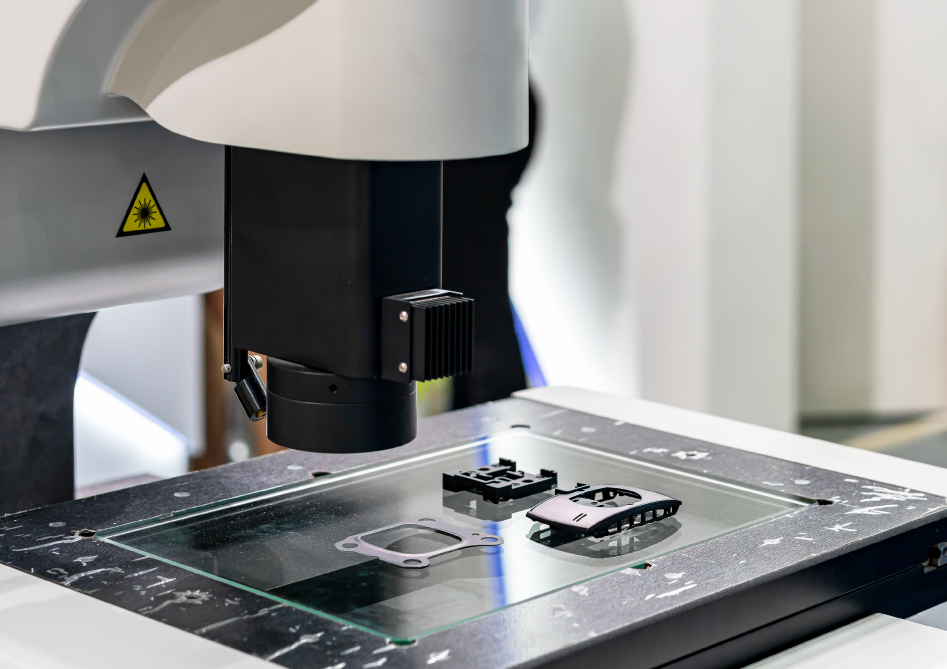

- Vision measuring machine (VMM).

- Coordinate measuring machine (CMM)

- Gauss meter.

- Surface roughness tester

- Millipore testing equipment in a climate controlled room.

- Automatic particle size analyser in a climate controlled room.

- Dry film thickness tester for measuring coating thickness.

- Weight measurement up to 4 digits.

- Microscope (100x)

- Multiple digital micrometre

- Low force vernier

- Sample profile cutting machine

- Customised thickness measurement table for measuring thickness of sheets up to 1.2mtr x 1mtr

- In-house product designing & development.

- In-house compound design & development.

- 3D Scanning for part analysis.

- Shore A & Shore M Hardness Tester’s.

- Mooney viscometer.

- Aging ovens.

- UTM for tensile and elongation testing.

- Rheometer.

- Cold chamber testing for brittleness.

- Compressibility & recovery machine.

- Specific gravity balance

- Compression set apparatus

- Melting point apparatus

- Butyl Rubber

- Neoprene or Chloroprene Rubber (CR)

- Ethylene Acrylic Elastomer (AEM)

- Ethylene Propylene Diene Monomer (EPDM)

- Fluorocarbon Elastomers (FKM, FPM & Viton)

- Hydrogenated Nitrile Butadiene Rubber (HNBR)

- Nitrile Butadiene Rubber (NBR)

- Natural Rubber (NR)

- Peroxide Vulcanized Compounds (EPDM, NBR, HNBR, FKM, ECO, CSM)

- Polyacrylate Elastomers (ACM) – Low, Normal & High Temperature

- Polyurethane Rubbers (PU)

- Silicone Rubber (VMQ)

- Styrene Butadiene Rubber (SBR)

- Various cork rubber grades

- IATF 16949 certified facilities by TUV

- REACH compliance certificates for selected materials.

- ROHS compliance certificates for selected materials.

- California Prop 65 compliant material (Wherever applicable)

- DVGW certification for selected materials.

- WRAS certification for selected materials.

- Check for export rating

- A climate controlled room with a completely access controlled automated chemical weighing system to ensure accuracy with weights and measures.

- 75 ltr & 35 ltr kneader for preparing master batches.

- Multiple two roll mixing mills with stock blenders.

- Calendars to ensure precise thickness and dispersion.

- Climate controlled rooms for pre and post compounding.

- Rubber pre-formers with cooling facility.

- Automated strip cutting machine.

- Isolated room for color compounded material.

- Multiple Transfer, Compression & Vacuum compression molding presses (250, 350, 400 & 650 Tonnage).

- Metal surface treatment facility for preparing parts for molding and bonding operation.

- Multiple gasket cutting and punching presses.

- Multiple laser cuttingbeds (6×8 ft.)

- Multiple Fecken Kirfel slicing and splittingmachines.

- Sanding machine to achieve accurate thicknesses.

- Nitrogen cryogenic de-flashing machine

- Clean room for contamination control.

- Automated ultrasonic washing machine for contamination removal.

- sCuring Oven for enhancing the physical properties of rubber molded parts.

- Charging Ovens for heating cork rubber blocks.

- Robotic arm lip trimming machines to achieve de-flashing in critical areas of seals.

- Automated de-flashing special purpose machines for flash removal.

- Band saw cutting machine.

- Laser engraving & inkjet printing machines for engraving and marking on parts.

- AI Based visual inspection machine for finished parts.

- Vision measuring machine (VMM).

- Coordinate measuring machine (CMM)

- Gauss meter.

- Surface roughness tester

- Millipore testing equipment in a climate controlled room.

- Automatic particle size analyser in a climate controlled room.

- Dry film thickness tester for measuring coating thickness.

- Weight measurement up to 4 digits.

- Microscope (100x)

- Multiple digital micrometre

- Low force vernier

- Sample profile cutting machine

- Customised thickness measurement table for measuring thickness of sheets up to 1.2mtr x 1mtr

- In-house product designing & development.

- In-house compound design & development.

- 3D Scanning for part analysis.

- Shore A & Shore M Hardness Tester’s.

- Mooney viscometer.

- Aging ovens.

- UTM for tensile and elongation testing.

- Rheometer.

- Cold chamber testing for brittleness.

- Compressibility & recovery machine.

- Specific gravity balance

- Compression set apparatus

- Melting point apparatus

- Butyl Rubber

- Neoprene or Chloroprene Rubber (CR)

- Ethylene Acrylic Elastomer (AEM)

- Ethylene Propylene Diene Monomer (EPDM)

- Fluorocarbon Elastomers (FKM, FPM & Viton)

- Hydrogenated Nitrile Butadiene Rubber (HNBR)

- Nitrile Butadiene Rubber (NBR)

- Natural Rubber (NR)

- Peroxide Vulcanized Compounds (EPDM, NBR, HNBR, FKM, ECO, CSM)

- Polyacrylate Elastomers (ACM) – Low, Normal & High Temperature

- Polyurethane Rubbers (PU)

- Silicone Rubber (VMQ)

- Styrene Butadiene Rubber (SBR)

- Various cork rubber grades

- IATF 16949 certified facilities by TUV

- REACH compliance certificates for selected materials.

- ROHS compliance certificates for selected materials.

- California Prop 65 compliant material (Wherever applicable)

- DVGW certification for selected materials.

- WRAS certification for selected materials.

- Check for export rating